Scania has been busy, beavering away at revisions to their 13-litre engine range. More than just tinkering, the company has invested some two billion Euros and five whole years in the research & development of the engine which, the company claims, will achieve fuel savings of some 8%.

“These new engines bring something outstanding to the market,” says Stefan Dorski, Senior Vice President, Head of Scania Trucks. “This shows how we at Scania are delivering on our mission, both in terms of our renowned customer focus and sustainability, with the science-based targets that we are committed to. The eight percent fuel savings the new powertrain offers are nothing but a game changer for our industry.”

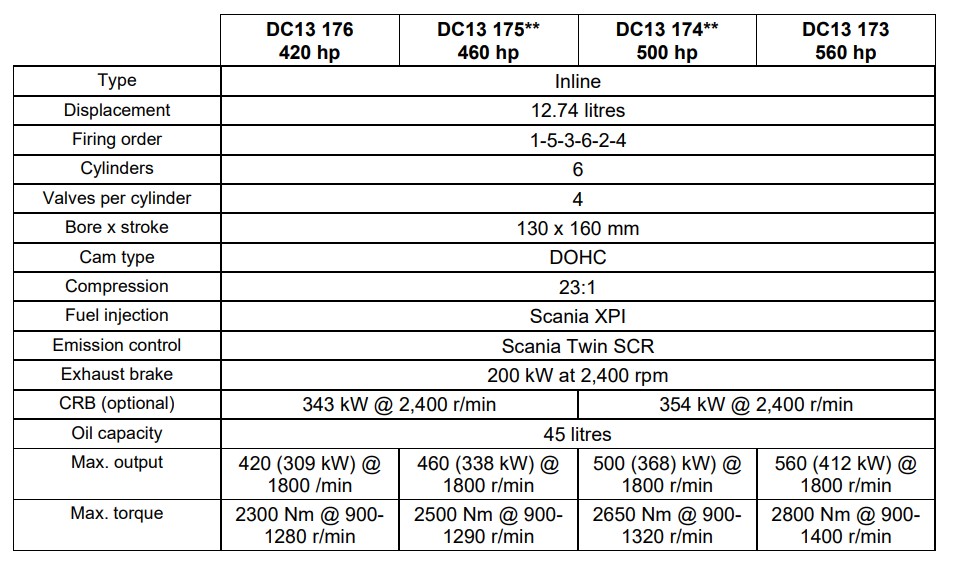

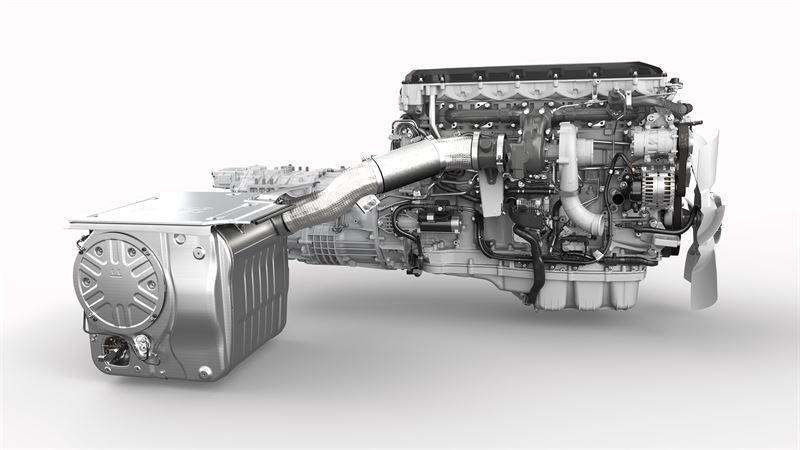

The new engine use twin overhead camshafts and matching twin SCR system to achieve the required efficiency.

“We knew from the beginning that dual overhead camshafts (DOHC) in combination with four-valve cylinder head technology and SCR only was a requisite,” says Magnus Henrikson, Chief Engineer and the person who has been heading the five-year development process. “With the DOHC solution in place, we were able to develop the optional Compression Release Brake system to the expected performance level. And precise valve control from overhead cams is also a must for the advanced Scania Twin-SCR system with dual dosing of urea.”

Scania claims that there has been no carry-over from the earlier range to the new one; it’s all been revised. There are new injectors and an optimised fuel pump. The crankshaft is weight and strength optimized for efficiency and durability; Scania’s new platform’s technical life-length has increased by 30% compared to the previous generation, despite decreased maintenance requirements.

The twin SCR system is not new; Scania introduced it for their V8 last year.

“By injecting a first dose of AdBlue in the close-coupled position to the turbo charger, immediately after the Exhaust Brake Flap where the exhaust gases are still very hot, we dramatically increase the total efficiency of the aftertreatment system. The second dose is then injected in the usual position inside the aftertreatment system. But by then the task is easier since the peak NOx level has already been reduced. The particulate filter, which is positioned between the two SCR catalysts, is regenerated without post-injecting extra fuel to the exhaust system. All-in-all the Scania Twin-SCR system is a clever way to make the best possible use of the energy in the exhaust stream,”says Henrikson.

It’s All About the Revs…

Scania’s low-rev philosophy is well-known in the transport industry. A truck that can cruise at just over 900 r/min will, in most operations, use less fuel. With the new range, Scania is taking this even further. The powertrain is regarded as an integrated unit where the engine, the aftertreatment system, the gearbox and the driven axle are working as a team, monitored by management systems with unique processing capabilities.

To that end, Scania is now introducing a new rear axle with fast gearing options; the fastest one is 1.95:1. The truck will normally try to run in 12th gear though, since that is the direct gear and offers the least transmission losses. The OD is only engaged when the conditions are favourable. This also means that the truck will probably do more shifting than some drivers are used to, in order to optimise the fuel savings.

“The introduction of the new Scania Opticruise last year opened up new possibilities for us,” says Henrikson. “It has a wider spread, with a direct 12th gear and a true overdrive gear on top, which means that we are able to lower the engine revs at cruising speed a bit further. In combination with the fast rear axle gearings, fuel savings of eight percent are possible”.

New Transmissions

Last year, Scania started to introduce a new range of automated gearboxes that eventually will replace all current automated Scania Opticruise solutions. G33CM was the first member of the new range, and it is now joined by the G25CM, an iteration aimed for slightly lighter operations. They will both be paired with the new Scania engines.

“The G25 and G33 are both indispensable for reaching the results we have achieved,” says Henrikson. “The Scania Opticruise gearboxes are the enablers, thanks to their spread, for the whole set-up with the engine torque at low revs and the fast axle gearings.”

The automated manual gearboxes under the Scania Opticruise name were first introduced in the 1990s. The latest generation, first represented by the G33CM, is some 60 kg lighter than the former ones due to all-aluminium housings and smaller dimensions. Another key achievement is lowered noise, a prerequisite for meeting legal demands.

Scania’s low-rev/high torque philosophy: how it works

Modern-day Scania diesels like the new range offer their peak torque from revolutions just a few hundred r/min above idling – and the torque build-up is very fast from idling.

The massive torque also means that these engines have extreme stamina – they keep on delivering the necessary torque and propulsion effortlessly at RPMs where engines of older generations would long since have demanded downshifts for higher revs. So how do Scania customers benefit from this?

The simple answer is that less revolutions also means less fuel injections (since a fourstroke engine needs a fuel injection on every fourth stroke). And when you pair the stamina from the new engines with the new gearbox, the new aftertreatment system and the new rear axles, you end up with excellent fuel performance since they all work together and are monitored and managed electronically in parallel.

This means that a regular > 40 tonnes tractor-and-trailer combination will typically cruise in 12th direct gear most of the time when laden. It does so by taking advantage of:

1) the torque from the engine

2) the low transmission losses on the direct gear

3) the fast gearing in the rear axle (made possible by the wide total spread in the Scania Opticruise

gearboxes).

And when the truck is lightly loaded or unloaded or going slightly downhill, the low-rev philosophy can be taken even further by engaging the true OD above the 12th direct gear.

Power Outputs

Initially, the new range will be produced with four different power output levels for Euro 6: 420, 460, 500 and 560 hp. It is only when mated to Scania’s new Opticruise gearboxes (G25 and G33 that was introduced in 2020) and a new range of driven Scania rear axles, that fuel savings of eight percent are achieved. All engines can be run on HVO, and two of them can be ordered for use with 100% renewable biodiesel.

Scania’s new 13 litre engine range – technical data