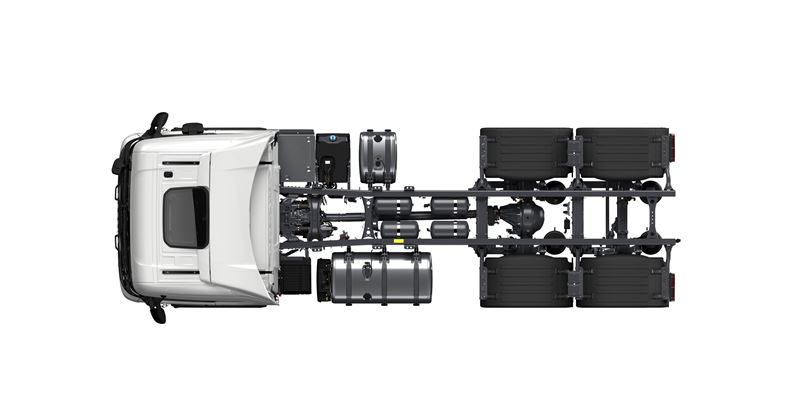

Alongside the launch of their new 13-litre engine, Scania have revised the way that their chassis are configured.

The system goes under the name ‘MACH’, Scania’s new Modular Architecture Chassis, which is much more flexible when it comes to personalising for individual customers.

It’s All About the Holes

The heart of the system is the introduction of a new set of rules for frame hole patterns, with dedicated holes for mounting parts both inside and outside the frame. The result is a more modular and predictable chassis layout, which increases the theoretical number of chassis layouts exponentially.

“Instead of getting stuck due to the dependencies between different components, we can now offer a greater variety for chassis layouts,” says Ola Brantefors, Head of Layout and Chassis Installation at Scania R&D. “It is from now on possible to pack the chassis, starting in front of the rear axle, for instance by putting a fuel tank there. That might mean that the payload improves by better weight distribution, while at the same time leaving room for objects like storage space or supporting legs in forward positions, closer to the cab.”

Fuel Optimisation Unit

A completely new range of diesel fuel tanks is also being introduced, ranging from 165 up to 700 litres each. There are basically three sizes (S, M and L), that also come in different lengths. They all have a new, ingenious D-shaped design that vastly improves their robustness and they are fitted to the frame with C-shaped brackets.

The low-pressure fuel pump, the primary fuel filter and the water separating filter are moved away from the engine itself and gathered in a separate fuel optimisation unit. This unit is mounted on the side of the primary tank. By doing so, Scania has now once and for all solved the classic challenge about how to be able to use all the fuel in the tank.

“Diesel engine fuel injection systems must not be allowed to suck in air, which is a risk when you have a long fuel tank and drive uphill or downhill, so that the fuel stays in one end of the tank for a while,” explains Brantefors. “Our fuel optimisation unit works as a catch tank that mitigates the problem by holding a sufficient volume of fuel for feeding the high-pressure system on the new engine. This means that we have been able to increase the usable amount of fuel in our tanks, since we no longer need to keep a ‘reserve’ level to avoid sucking in air.”

Scania has also developed a new, smart solution for securing the fuel distribution between the tanks on trucks with dual tanks. By having a T-connection with a separate and constant (but very limited) feed to the fuel optimisation unit, a venturi effect is created, which ensures that no pockets of air block the feed between them over to the primary tank.

Greater flexibility

Other improvements that come with Scania’s new modular chassis layout are a couple of new AdBlue tanks for improved volume and these can be mounted on the frame. Scania is also introducing new ‘wet kit’ tanks for hydraulic auxiliaries (such as cranes) with the same D-shaped design as the fuel tanks. There are also new options for the air tanks, with brackets and piping that take full advantage of the new hole patterns from the flexible chassis layout and create new potential installation positions.

“The MACH solution really opens up for greater flexibility in a multitude of ways,” says Brantefors. “And objects such as spare wheels and storage boxes and what have you can now be fitted in many new and flexible ways. This is something that will be really appreciated by both customers and truck body builders.”

The aftertreatment system – a vital but rather large object on all modern trucks – can now be fitted in three standard positions with a choice of outlets in different directions. All the outlets are bigger than before, thus reducing the velocity of the exhausts and the potential problem with dust. And if these basic positions are not enough, the aftertreatment system can in fact be mounted in a free position on the frame, since Scania is also supporting truck bodybuilders with guidelines for unique installations.

“All-in-all, we believe that these changes will contribute in a multitude of ways to our customers’ daily operations,” says Brantefors. “We continue along the path where tailormade solutions for each customer is the hallmark of Scania’s offer, be it optimised loadcarrying capacity or the ability to actually use all the fuel that is on board the truck. And by taking out previous limitations we are also making life easier for truck bodybuilders that are looking for space for their superstructures and equipment.”