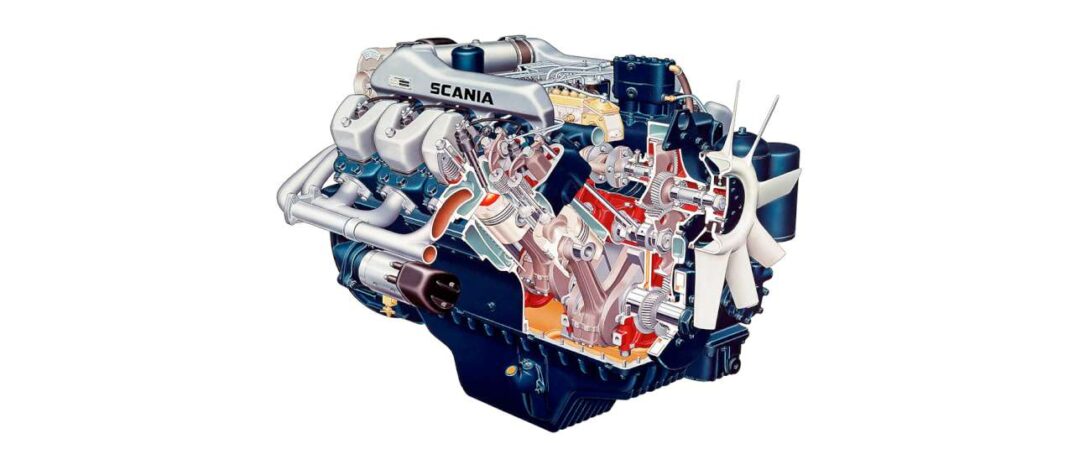

It is the most talked about engine that has been fitted to any truck across the world. Every driver wants to be sitting atop a Scania V8 powerplant. We chart the progress of this icon from its humble beginnings as a 14-litre with 350 horsepower over fifty years ago back in 1969 to the high tech 16.4 litre 770hp beast that graces the current line up. As one of the most searched for terms on Truckpages, ‘Scania V8 for sale‘ we felt it worthwhile reproducing the history of the engine.

1969 – 1976 Scania 140

- Swept volume: 14.2 litre

- Top output: 350 hp

- Max torque: 1,245 Nm

When Scania unveiled its 350 hp 14-litre V8 engine at the end of the 1960s, it was Europe’s most powerful truck engine, and it held that distinction for many years. The V8 made Scania the King of the Road.

12,160 vehicles sold

1976 – 1980 Scania 141

- Swept volume: 14.2 litre

- Top output: 375 hp

- Max torque: 1,480 Nm

With the introduction of a forward-located front axle on the LB series in 1975, Scania paved the way for V8 trucks in Brazil. This modification was made in order to meet limits on axle weight. Known locally as the LK series, these trucks were also built for the Australian market between 1976 and 1981.

20,707 vehicles sold

1980 – 1988 Scania 142

- Swept volume: 14.2 litre

- Top output: 420 hp

- Max torque: 1,725 Nm

In 1982, charge-cooling became optional on all V8 trucks, raising the maximum power output to 420 hp. Three years later, chargecooling became standard.

36,931 vehicles sold

1987 – 1996 Scania 143

- Swept volume: 14.2 litre

- Top output: 500 hp

- Max torque: 1,940 Nm

Scania Electronic Diesel Control was introduced in 1987, resulting in a maximum power output of 470 hp and a hefty 1,940 Nm torque.

51,811 vehicles sold

1995 – 2001 Scania 144

- Swept volume: 14.2 litre

- Top output: 530 hp

- Max torque: 2,300 Nm

The Bertone-designed 4-series trucks were named International Truck of the Year 1996. The jury was impressed by Scania’s fully integrated powertrain, featuring the engine, electronically regulated gearbox and integrated retarder.

34,450 vehicles sold

2000 – 2004 Scania 164

- Swept volume: 15.6 litre

- Top output: 580 hp

- Max torque: 2,700 Nm

The 16-litre V8 engine launched in 2000 and fitted in R164 and T164 trucks was a completely new design, based on the modular cylinder concept that applies to all Scania engines.

22,267 vehicles sold

2004 – 2016 Scania R Series

- Swept volume: 15.6/16.4 litre

- Top output: 730 hp

- Max torque: 3,500 Nm

Scania’s new R-series range was named International Truck of the Year 2010. The jury noted the aerodynamic design, the operational economy and the support system that spurs the driver to adopt more efficient driving habits.

80,000+ vehicles sold

2013 – 2016 Scania Streamline

- Swept volume: 16.4 litre

- Top output: 730 hp

- Max torque: 3,500 Nm

Scania introduced its new Streamline trucks in 2013 along with its second generation Euro 6 range, including the 520, 580 and 730 hp V8 engines. With its advanced aerodynamics, the new Scania Streamline provided fuel savings of up to 8 percent.

2016 – 2020 “New Truck Generation”

- Swept volume: 16.4 litre

- Top output: 730 hp

- Max torque: 3,500 Nm

A new generation of trucks was also the starting point for the new Scania V8 engine platform, offering substantial fuel savings compared to its predecessor. During 2017 the new generation V8 line up was completed with new 520, 580 and 650 hp engines. Also the 730 hp engine was further refined to deliver an additional 2 % reduction in fuel consumption.

2020 – 2024 THE CURRENT RANGE

- Swept volume: 16.4 litre

- Top output: 770 hp

- Max torque: 3,700 Nm

Scania introduced its new four-pieced V8 range, crowned with the yet most powerful: 770 hp, delivering 3700 Nm of torque. Scania once again offered record power levels combined with improved fuel efficiency by at least 6 %. Favourable CO2-per-tonne calculation could thus be achieved, especially when running on renewable fuels.